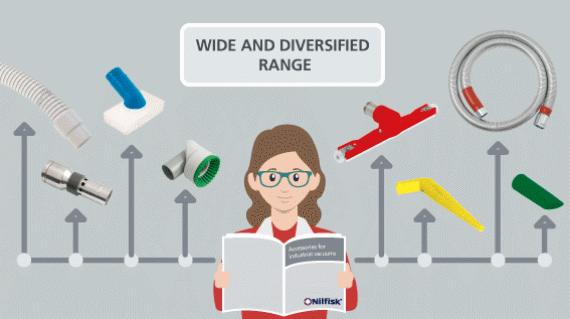

Using the right accessory or optional means getting the maximum result from any action because they make your daily work easier and efficient, enhancing the performance of your Nilfisk industrial vacuum.

The difference between accessories and optionals is the following:

- ACCESSORY: everything which is outside the machine, from the inlet to the terminal tools

- OPTIONAL: it is mounted on the machine, it is used to upgrade the machine to get new functionalities

Accessories

Discover our range of accessories, specific for the different applications:

- Colored, FDA accessories for food

- Silicone, autoclavable accessories for pharmaceutical

- Easy-to-use and reliable accessories for any applications

- Accessories for the recovery of hot material

- Accessories for overhead cleaning

Optionals & Separators

The wide variety of optionals allows the best results to be obtained in every operational context, with immediate advantages and benefits in terms of savings in time and resources.

Separators are containers placed between the vacuum point and the vacuum cleaner and are the most effective way to vacuum and collect solids or liquids without having to use the container on the vacuum cleaner.

Accessories

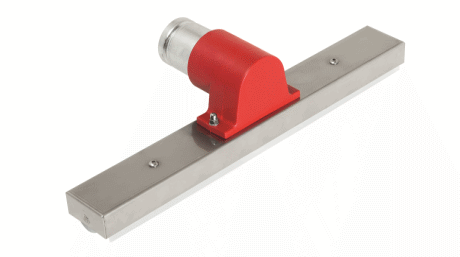

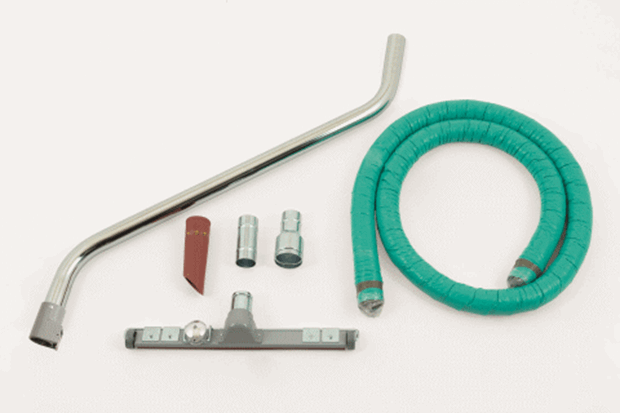

Accessories for general applications

Nilfisk provides different accessories according to the different applications. Here is just a selection of the most common accessories kits, designed to meet different needs.

- General cleaning kit (ø 40 and 50 mm): suitable for light applications, it is extremely versatile.

- Industrial cleaning kit (ø 40, 50 and 70 mm): ideal for cleaning spacious areas, this kit allows a fast and effective cleaning.

- Cleaning machinery kit (ø 40, 50 and 70 mm): ideal for cleaning dust and residues from machinery used during the production process.

- Floors and machinery oilproof kit (ø 40, 50 and 70 mm): ideal for treating all surfaces where oils have to be collected.

- ATEX kit (ø 40 and 50 mm): optimal solution when conductivity is a must. Available in three different versions, these sets consist of conductive or antistatic elements.

Accessories for the food industry

Accessories for industrial vacuums: colored, innovative.

Colored, FDA approved, autoclavable.

Efficiency

Hygiene

Wide choice

Safety

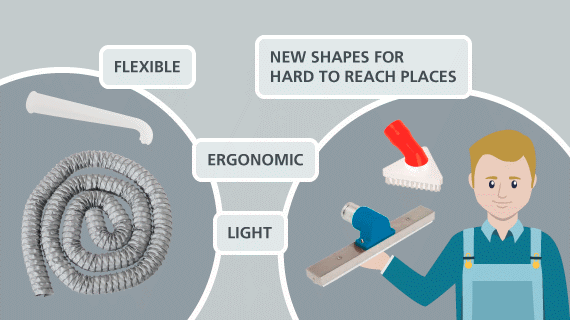

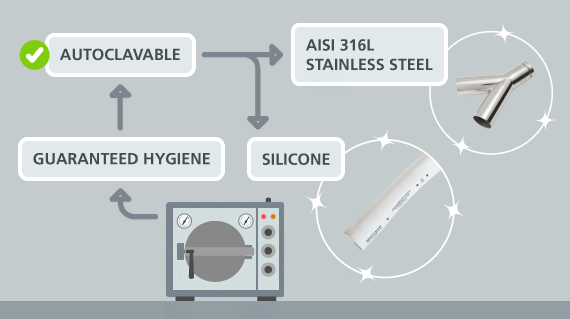

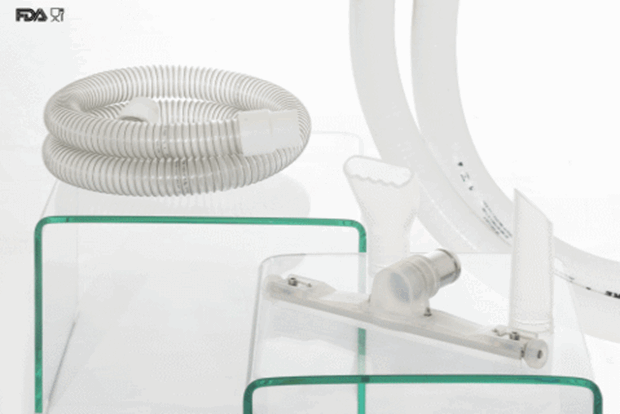

Accessories for the pharmaceutical industry

New FDA approved accessories specific for industrial vacuum cleaners operating in the pharmaceutical production plants.

Nilfisk accessories for pharmaceutical applications are designed to meet any possible need in terms of safety, hygiene, and efficiency.

Here the main features:

- Light and flexible

- FDA and EC 1935/2004 approved

- AISI316L, Silicone

- They can be sterilized in autoclave

Nilfisk accessories for the pharmaceutical industry: inspired by your need of certified hygiene.

Accessories for the recovery of hot materials

A specific range for high temperatures is available, in order to meet any need in ovens cleaning and high-temperature material collection. Solve immediately the problem to clean the oven, even in the deepest part, keeping the product quality at the top.

When things heat up, we go into action!

ATEX certified accessories

Do you long for never-ending SAFETY?

The only safe way is the one without contingencies.

Discover the new range of ATEX accessories to be connected to the Nilfisk explosion-proof industrial vacuums, certified by a notified body for total safety.

Safety is one of the most important concept in Nilfisk philosophy.

A new complete range of ATEX accessories suitable for II 2D 2G has been developed and certified by a notified body.

Discover the new closed circuit concept applied along the whole accessories sequence, from the vacuum cleaner to the terminal tool.

Why should you use ATEX certified accessories? To avoid explosion risks.

Unique accessory attachments avoid any improper use. In this way, the operator can only use accessories suitable for use in ATEX environments. All the connectors are electrochemical marked indicating the same reference reported in the test report and on the official certificate.

Available documentation: certificate, test report, new user manual for EX accessories, and attestation of conformity.

What is the CLOSED CIRCUIT? It is your warranty for total safety

The connection that creates the closed circuit is easy, smart. There are male and female parts to be connected, starting from the new inlet. The parts have a block to avoid the usage of not tested accessories. With the closed circuit concept, Nilfisk takes the responsibility for the choice of safe and tested accessories for the operator, to prevent misusage, possible mistakes, or even explosion risks.

Optionals & Separators

Optionals

You can expand the potential of your vacuum cleaner and use it for various jobs to meet specific requirements only mounting an optional. The wide variety of optionals allows the best results to be obtained in every operational context, with immediate advantages and benefits in terms of savings in time and resources. You can choose systems to separate liquids from solids, as well as automatic stops, or different types of filters, or many other options that will allow you to upgrade the vacuum cleaner according to your needs.

Separators

Separators are containers placed between the vacuum point and the vacuum cleaner, and are the most effective way to vacuum and collect solids or liquids without having to use the container on the vacuum cleaner.

For example, if you need to vacuum large amounts of very fine dust, the separator offers the advantage of collecting almost all the vacuumed dust to prevent clogging the vacuum cleaner filter, guaranteeing a longer working life and consistently high performance from the vacuum cleaner. When vacuuming liquids, there is no risk of getting the filter wet and having to replace it often, for the above reasons.

Separators are added value in all intensive applications, offering immediate benefits, saving time, extending the life of the vacuum cleaner and its components, offering greater operational efficiency, safety and environmental protection.

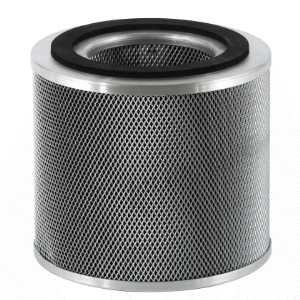

Filters and filter cleaning systems

The filter is the lung of the vacuum cleaner, and traps all the impurities avoiding them to be blown back into the environment, in order to protect the health of the operators. Nilfisk uses the highest quality filters on its vacuum cleaners; these filters can be divided into 3 main categories:

1. Primary filters (bag, star or cartridge type)

2. Absolute or secondary filters

3. Activated carbons filters

Primary filters

The primary filters are mounted on all vacuum cleaners and trap all forms of common dust, even the finest particles; There are different types of primary filters:

- Bag filters

- Star filters

- Cartridges (used as primary filters allow the industrial vacuum to run continuously without stopping for the filter cleaning)

These filters can be in L and M class for the collection of hazardous dust and they can be in different media for the different applications such as for example in PTFE (thanks to the PTFE membrane, dust falls down easier during the filter cleaning and doesn't penetrate the filter material) or Nomex® (to be used in case of hot material).

Absolute filters

When the potential hazardous dust has to be collected further absolute H class filters are needed, Nilfisk provides both upstream (located before the blower) and downstream (as last filtration stage) absolute filters. In terms of filtration efficiency the filters can be HEPA 14 and ULPA 15.

Activated carbons filters

Activated carbon filters are mainly used for the following applications:

- When malodorous materials must be removed.

- When a low concentration of pollutants must be removed as in laboratories, electronics, pharmaceutical industries.

Filter cleaning systems

A clean filter allows your vacuum to keep the highest performance, so the filter cleaning system is a key point. Nilfisk offers different types of systems, from the manual to the most automatic.

- FILTERSHAKER: manual or electric, it is easy to use and effective. Ideal for vacuum cleaners working periodically, as it needs the vacuum to be switched off to perform the filter cleaning operation.

PULLCLEAN: the filter can be cleaned while the vacuum is running, you only have to close the inlet and pull the flap several times.

INFINICLEAN: it is completely automatic and stand-alone and cleans the cartridges filter while the vacuum cleaner is working.

PULSE JET SYSTEM: it is completely automatic and powerful and it needs to be supplied with compressed air.

![Atex[1] Ps Onethirdscreensize Cs Onethirdscreensize THCOCJ](https://pim-images-live.azureedge.net/media/20996/atex-1-ps-onethirdscreensize-cs-onethirdscreensize-thcocj.jpeg)